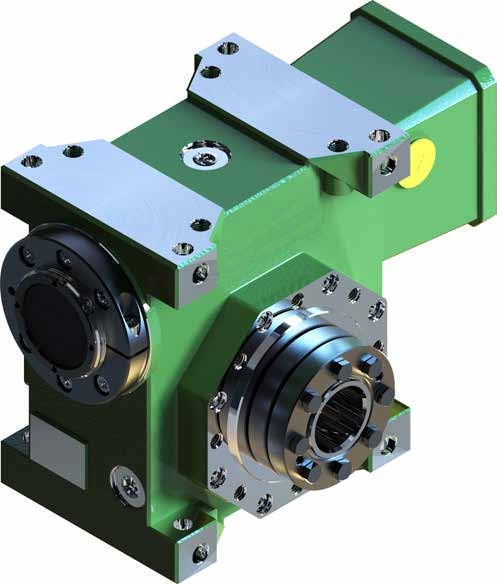

JDLB Options

Servo worm gear units have six kinds :45 – 50 – fifty five – 63 – 75 – 90, with dual lead worm drive. Left and correct flank of worm shaft working with various lead angle leading to tooth thickness gradual change. In order that you may move worm shaft

and alter backlash.

JDLB Applications

Precision rotary motion

— Minimizing the noise and vibration that is brought about by the load change and the

alter of cutting force.

— minimizing the noise and affect that is caused by the corotation and reverse.

— By minimizing worm abrasion.

— Rising worm output response speed.

Precision Indexing device

— CNC machine, assembly line, cutting machine, transmission

— Indexing gadget, correct studying mechanism need exact motion

events.

Velocity transforming conditions.

— Minimizing the noise as well as impact that is definitely induced by speed transform.

— Cutting down the worm abrasion that is definitely caused by velocity modifications.

JDLB Make option

The next headings incorporate information on critical aspects for

selection and right utilization of gearbox.

For unique information about the gearbox range, see the related chapters.

EFFICIENCY

Efficiency can be a parameter which has a key influence on the sizing of specified applications, and mainly depends on gear pair style and design aspects.

The mesh information table on page 9 shows dynamic efficiency (n1=1400)and static efficiency values.

Do not forget that these values are only achieved right after the unit continues to be run in and is on the doing work temperature.

JDLB reducer1

Tags: