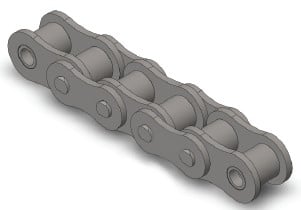

Roller chains are one particular of your most effective and cost eff ective tips on how to transmit mechanical electrical power concerning shafts. They operate over a broad variety of speeds, manage big doing work loads, have extremely tiny vitality losses and are commonly low-cost in contrast with other methods

of transmitting electrical power. Prosperous variety involves following quite a few comparatively uncomplicated actions involving algebraic calculation as well as the use of horsepower and services issue tables.

For almost any given set of drive circumstances, there are a variety of doable chain/sprocket confi gurations that could successfully operate. The designer as a result really should be aware of many simple choice concepts that when applied correctly, help balance total drive functionality and value. By following the measures outlined on this area designers need to be able to make choices that meet the needs with the drive and therefore are price eff ective.

Standard Roller Chain Drive Concepts

? The advised amount of teeth for that little sprocket is 15. The minimum is 9 teeth – smoother operation is obtained with extra teeth.

? The recommended greatest variety of teeth for the massive sprocket is 120. Note that even though more teeth lets for smoother operation having also lots of teeth leads to chain jumping off the sprocket just after a relatively compact quantity of chain elongation because of dress in – That is chains by using a really huge variety of teeth accommodate significantly less wear ahead of the chain will no

? Speed ratios should be seven:1 or much less (optimum) and not higher

than ten:one. For greater ratios the use of several chain reductions is recommended.

? The advised minimum wrap of your small sprocket is 120°.

? The recommended center distance involving shafts is 30-50 pitches of chain. There are actually two exceptions to this as follows:

one. The center distance should be higher than the sum from the outdoors diameters of the driver and driven sprockets to avoid interference.

two. For speed ratios greater than three:1 the center distance should not be much less compared to the outside diameter in the significant sprocket minus the outdoors diameter in the modest sprocket to assure a minimal 120° wrap close to the smaller sprocket.

ASME/ANSI Drive Chain

Tags: