Aspects Affecting Choice

The next is often a checklist on the information necessary to help in generating a coupling selection. Not all of those goods will come into perform in all selection processes. These products involve, but usually are not restricted to:

Application connected:

Application facts

Sort of motor and driven products

Motor horsepower or KW

Operating/coupling pace

Shaft sizes and separation

Room and dimension constraints

Natural environment (temperature, chemicals, and so on)

Stability prerequisites

Distinctive modifications

Steps In Picking A Gear Coupling

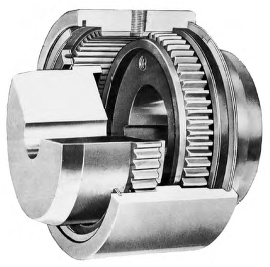

Refer towards the gear coupling specs charts displayed with each form of coupling through the entire Gear Coupling Products segment of this catalog. The pictures and charts present visualization, specs, and dimensional information for its broad variety of gear coupling goods. Generally begin with an F Style flanged gear coupling or even a C Sort constant sleeve gear coupling (web page G-16) and proceed from there.

Stage 1: Evaluate the gear coupling series and variety as selected to ensure the variety

meets application needs.

Phase two: Establish the nominal application torque in in-lbs through the use of the next formula:

Application Torque ( in-lb ) = (HP x 63025)/RPM

Or Nm = (KW x 9550)/RPM

Stage three: Assessment the Application Services Component chart for the services component quantity linked using the application the place this coupling are going to be applied. Multiply the application torque from the application services component to find out the total torque demanded for the coupling selection.

Step 4: Assess the expected total torque value using the nominal torque capability

listed inside the Gear Coupling Selection chart for your sought after coupling type.

Stage five: Verify the greatest bore dimension as well as greatest RPM with the coupling

variety picked

Stage six: Note any distinctive prerequisites which include the BSE dimension for floating shaft and spacer kinds, shear pin torque, slide coupling facts, mill motor tapered shaft data, and any other pertinent information.

Gear Coupling Selection System

Tags: